Commercial HVAC Cost Calculator | Estimate 2025 Prices & Metrics

Aug 7th 2025

Commercial HVAC Cost Calculator — Estimate Your Project Cost (2025 Edition)

Estimating the cost of a commercial HVAC system can be complex. Instead of guesswork, use a structured **commercial HVAC cost calculator** that takes into account factors like building size, system capacity, and installation complexity. In this guide, HVACProSales.com walks you through how to estimate costs, what variables drive pricing, and how to use your estimate to plan budget and proposals.

? What Is a Commercial HVAC Cost Calculator?

A commercial HVAC cost calculator is a modeling tool that estimates the total cost (equipment + labor + materials + overhead) based on variables like system tonnage, building use, ductwork, and project complexity. While tools like SageCalculator’s version occasionally go offline, the method is consistent: assign cost per ton and adjust for margins, complexities, and scale.

? Estimation Formula & Base Rates

A common baseline is:

Estimated Cost = (Installed Cost per Ton) × (Total Tons) × (Adjustment Factor for Complexity)

In 2025, typical installed cost per ton (equipment + labor) for commercial systems ranges from $1,200 to $2,800 per ton, depending on region, system type, and complexity.

? Sample Cost Range by Building Type

| Building Type | Tonnage Range | Estimated Cost Range |

|---|---|---|

| Small office / retail (2,000–10,000 sq ft) | 5 – 20 tons | $6,000 – $56,000 |

| Large retail / warehouse (10,000–50,000 sq ft) | 20 – 100 tons | $24,000 – $280,000 |

| High-rise / multi-tenant (100,000+ sq ft) | 100 – 500+ tons | $120,000 – $1,400,000+ |

⚙️ Key Cost Drivers & Adjustment Factors

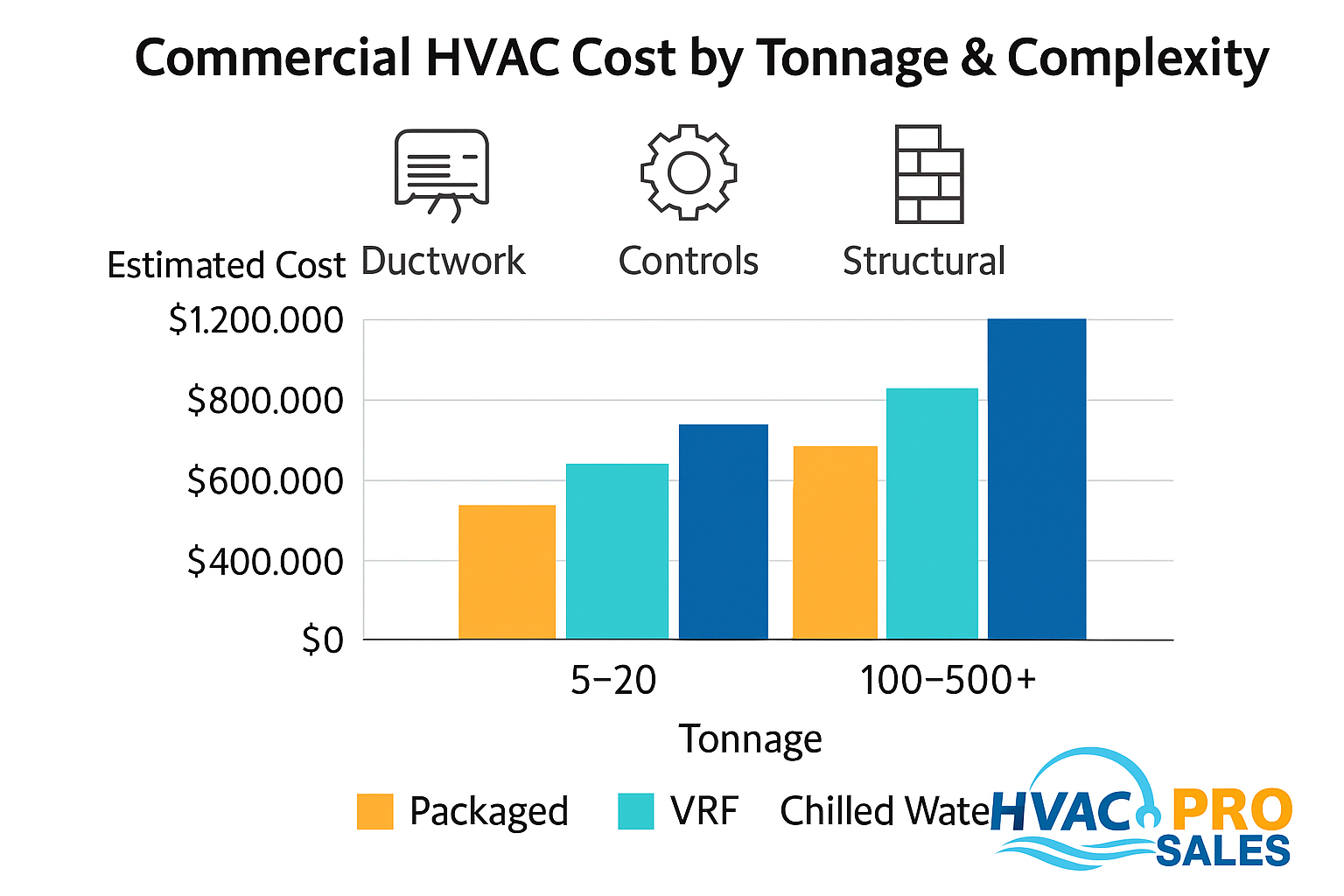

- System Type: VRF, rooftop packaged units, chilled water systems, or VAV systems differ widely in price.

- Ductwork Scope: New duct installation, retrofitting, or extensive layout changes raise cost.

- Controls & Zoning: Smart thermostats, building automation, and zones increase complexity.

- Roof Penetrations & Structural Work: Penetrating roofs, reinforcing mounts, or curb frames adds labor.

- Accessibility & Hours: Working in confined spaces or off-hours shifts the cost upward.

- Permits & Engineering: Local requirements, design drawings, structural and civil costs must be included.

? How to Use the Estimate for Proposals

- Determine building tonnage requirement (via load calculation or rule-of-thumb estimate).

- Select your desired system type (packaged roof, VRF, chilled water, etc.).

- Apply base installed cost per ton *and* complexity multiplier (e.g. 1.2–1.5× for difficult installs).

- Include allowances for ductwork, controls, structural, and contingencies (10–15%).

- Validate with quotes from manufacturers or local commercial HVAC contractors.

? Tips to Keep Cost Under Control

- Design early with flexible duct or VRF paths to minimize retrofit work.

- Bundle system orders and accessories (grilles, dampers, sensors) to reduce markups.

- Prefer prefabricated duct modules or modular systems to reduce field labor.

- Schedule installs in shoulder season for lower labor rates and better timing.

- Select proven brands with good warranty support and parts availability.

✅ Final Thoughts

A commercial HVAC cost calculator gives you a structured starting point—but real bids depend on project complexity, building constraints, and system choice. Use your calculated range to vet contractor proposals, negotiate pricing, and manage expectations. For quality parts, control systems, and tools for commercial installs, trust HVACProSales.com.

© 2025 HVACProSales.com | Contact Us | Shipping & Returns | Privacy Policy