Hard Start Kit Installation: When and How to Do It Right

Nov 5th 2025

When and How to Install a Hard Start Kit: A Technician's Guide

Hard start kits can be a powerful tool for solving compressor starting issues, especially in hot, humid markets like Miami and South Florida. But they are not a cure-all. Understanding when they help, when they don’t, and how to install them correctly is critical if you want to protect the compressor and avoid “band-aid” repairs.

This guide is written for working HVAC technicians across the United States who troubleshoot hard-starting systems on heat pumps, condensers, and package units. For OEM-style solutions, you can browse: Five Two One Compressor Saver and Capacitors & Hard Start Kits.

When to Consider a Hard Start Kit

A properly sized, quality hard start kit can reduce inrush current, help marginal compressors start more smoothly, and stabilize systems fed by weaker power. Before you install, always perform basic diagnostics with a professional HVAC multimeter or clamp meter and compare to manufacturer specs.

- Hard-Starting Compressors: Units that struggle to start, especially during peak afternoon loads in high ambient conditions, may benefit from a hard start kit once mechanical and electrical issues have been ruled out.

- Frequent Circuit Breaker Tripping: If the breaker trips on startup due to high inrush but checks good otherwise (proper wire size, breaker size, and compressor amps), an OEM-approved or quality aftermarket kit can help.

- Voltage Drop Issues: In areas with weaker power, long wire runs, or marginal service drops, a hard start kit helps compressors start more reliably at slightly lower voltage. You should still document voltage at startup with HVAC-rated meters and address supply issues when possible.

- Older Systems: Aging compressors with worn internal components may start more smoothly and run cooler when assisted by a properly matched hard start kit, extending usable life when replacement is not immediately feasible.

Many technicians standardize on proven options like Five Two One Hard Start Kits for residential condensers and heat pumps because they’re quick to wire and backed by field experience.

Proper Installation Steps (Field Basics)

Important: Only qualified, licensed HVAC professionals should install hard start kits. Always follow the equipment manufacturer’s instructions and the hard start kit wiring diagram. The steps below are a general field overview, not a substitute for OEM documentation.

1. DISCONNECT POWER

Open the outdoor disconnect and verify power is off at the unit using a CAT III or better meter.

2. Discharge the Run Capacitor

Confirm the run capacitor is fully discharged using safe procedures and tools rated for the job. Replace any bulged, leaking, or out-of-spec capacitors from Capacitors & Hard Start Kits before adding a kit.

3. Mount the Hard Start Kit Securely

Mount the kit inside the control compartment or on a stable surface away from moving parts and hot discharge lines. Use provided brackets or approved fasteners so it can’t vibrate loose.

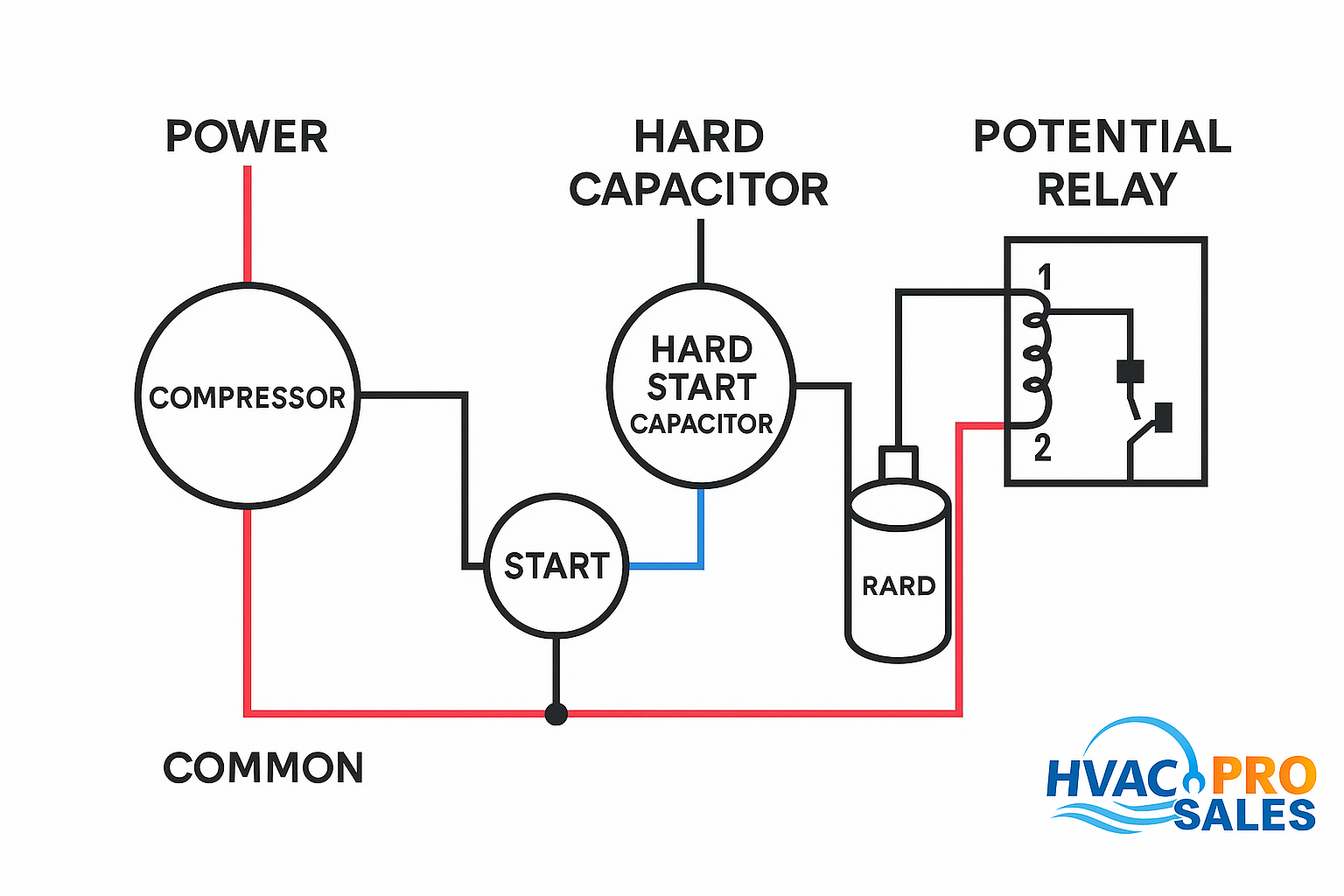

4. Wire According to the Manufacturer Diagram

Follow the wiring diagram on the hard start kit and the unit’s schematic. For OEM-style kits like Five Two One, lead connections are clearly labeled. If there is any conflict between diagrams, defer to the equipment manufacturer.

5. Verify All Connections

Tug-test all terminals, confirm no exposed bare conductors, and ensure wires are routed away from sharp edges, fan blades, and hot surfaces. Use proper HVAC wiring connectors and approved methods.

6. Restore Power and Test Operation

Close the disconnect, then start the system from the thermostat or test mode. Observe startup, listen for abnormal sounds, and check amperage and voltage during start using meter and clamp tools. Document LRA/starting amps before and after installing the kit.

When NOT to Use a Hard Start Kit

Hard start kits are not a magic fix for every compressor problem. Installing one on a failing compressor without proper diagnosis can mask the real issue, create liability, or lead to a repeat call.

Avoid using hard start kits as a band-aid solution for:

- Mechanically Locked Compressors: If amp draw is extremely high, the compressor won’t budge, and you’ve verified proper voltage and components, the compressor may be mechanically locked. A hard start kit won’t “save” it.

- Electrical Shorts in Compressor Windings: If insulation tests fail or windings test shorted or grounded with meters and megohm testers, do not add a hard start kit.

- Severely Low Refrigerant Charge: Low charge issues should be addressed via proper leak detection and repair. For professional tools, see Leak Detectors & UV Dye Kits.

- Failed Start Components: Replace failed capacitors, contactors, or relays with OEM or high-quality parts from Contactors & Relays and Capacitors & Start Components before considering a hard start kit.

In borderline cases, advanced testing with HVAC diagnostic analyzers can help document compressor health and support your replacement vs. repair recommendations.

Frequently Asked Questions

Q: Will a hard start kit reduce my compressor's life?

A: When properly sized, wired, and applied, a good hard start kit usually reduces startup stress and can extend compressor life—especially on marginal power or older equipment. Problems arise when oversizing, miswiring, or using a kit to prop up a compressor that is already failing. Stick with quality products from Five Two One and follow manufacturer guidelines.

Q: Can I install a hard start kit on any AC unit?

A: Most reciprocating compressors benefit from a properly selected hard start kit. For scroll compressors and inverter-driven systems, always check the equipment manufacturer’s recommendations—some brands discourage or limit aftermarket kits. When in doubt, consult OEM literature or tech support before installing.

Q: How do I explain a hard start kit to homeowners?

A: Many techs describe it as a “booster” that helps the compressor start more easily, especially during extreme heat or under marginal power conditions. It’s not a guarantee against future failures, but when applied correctly and documented with before/after measurements, it can be part of a professional, transparent repair strategy.

Need Reliable Hard Start Kits for the Field?

Stock your truck with proven hard start kits, capacitors, and diagnostics so you can solve tough starting issues quickly and confidently—on rooftop units, heat pumps, and condensers from Miami to any market in the U.S.

Shop Capacitors & Hard Start Kits Shop Five Two One Compressor Saver